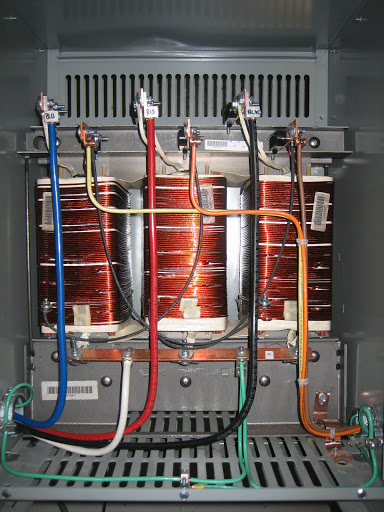

The heart of TP Power Services is the installation and commissioning of distribution and power transformers. We both manufacture and install the units and have a wealth of experience in both liquid filled and cast resin (dry type) transformers. Whether you want us to install one of our own units or a unit by another manufacturer (domestic, European and global) we can provide a professional service by experienced teams. These teams will work with you on your requirements and find a solution that fits your needs, whether on a small distribution unit or a Generator or Grid transformer.

Our teams pride themselves on providing high quality results and will liaise with your throughout the installation, ensuring asset integrity and quality control throughout. They have access to a vast array of equipment to assist them in the installation, including but not limited to:

- vacuum and air dry pumps

- dew point measuring equipment

- digital test sets

- bespoke lifting sets to protect assets during erection

Depending on your requirements we will develop a testing schedule and ensure that robust testing methods are applied to guarantee the integrity of your new unit. This includes all control and protection equipment.

Delivery, offloading and final positioning of the unit will be overseen by our team who will liaise and work with the haulage contractors bringing the unit onsite. They will then oversee the handling, filling and processing of both the mineral oil and synthetic fluids whilst ensuring unit integrity and quality assurance.

Relocation Service

Do you need your transformer to be relocated? We at TP Power Services can provide all services from dismantling through to re-installation and commissioning to ensure that your productivity is unaffected. We provide expert teams who can deal with transformers of all sizes. Smaller units can be relocated with ease, however for larger transformers there is a process of planning and control measures that needs to be completed prior to dismantling from the current location. This ensures the integrity of the asset and ensures that all of the ancillary components and windings are protected. By using effective planning and management we can ensure that your transformer is relocated with minimum disruption to your business and guarantee the integrity of your power assets.

As part of the planning and quality control we will provide you with a comprehensive bespoke document set including the following:

- interchangeability studies

- project schedules

- safe working documents

- heavy haulage route plans

- quality control plans.

Prior to beginning work the team will conduct a preliminary schedule. This will ensure that the transformer can be relocated and can then be used as a benchmark after relocation by comparing test results.

Any mineral oil in the unit may need to be removed prior to the relocation and stored until the transformer has been recommissioned. After the cooling system has been dismantled, nitrogen or dry air will be used on the main tank to purge the system and reduce the risk of fire. Prior to loading onto the transport, impact recorders and indicators will be fitted. This also ensures the integrity of the asset during transportation to the new location.

On arriving at the new locations, the unit will be offloaded and re-positioned in accordance with the original schedule. Integrity testing and connections will then be checked prior to the installation. This would highlight any problems that have occurred during transit and allow any damage to be identified.